Link Barricades are manufactured through the plastic injection molding process, which essentially consists of injecting molten polypropylene into a mold cavity, where the plastic material solidifies in the shape of a barricade.

Without generating any residue or waste, all plastic material used in the manufacturing can be crushed and returned to the process.

Yes, the injection molding process combined with our raw material engineering makes it possible to recycle Link Barricades into new barricades, without compromising the quality or the ecosystem. We are proud to be the only supplier in the industry to develop a solid sustainability program based on environmental responsibility and investment.

Yes! They are developed for unrestricted use (internal and external), Link Barricades have Anti-UV protection additives that stabilize mechanical and visual properties.

Yes! Link Barricades are manufactured with high strength polypropylene, which and can be considered one of the most robust plastic parts manufactured in Brazil. By comparison, they weigh the same as 6 plastic chairs, and they support more than 300kg.

The Barricades can be customizable; however, they are manufactured without any customization. All accessories, such as stickers, plates or canvas, can be added to the order and the barricades are delivered customized.

Yes, Link Barricades feature an ergonomic handle that allows one person to carry with only one arm and minimal effort, preventing occupational illnesses. One person carries two barricades easily.

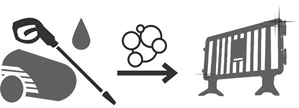

For cleaning and maintenance, we recommend the use of a high-pressure washing machine and neutral soap. Abrasive cleaners based on ammonia, bleach, or chlorine should not be used.

For a more efficient cleaning of incrusted dirt, we have an approved concentrated soap that does not damage the plastic of the barricades.

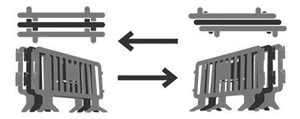

Link Barricades can be stored queued in two ways:

Standard and Optimized.

Standard – Barricades are queued by fitting the feet. The Standard Queue has a width of 2m and increases the length by 7cm for each stored barricade.

Optimized - Barricades are queued by alternating the fit of the feet. The optimized queue has a width of 2.22m and increases the length by 5cm for each stored barricade.

Of course! For safety reasons, we recommend stacking up to 3 floors and using a thinner plywood (5mm to 10mm) at each level to protect the barricades and increase stability.

A Standard Queue of 50 Link Barricades occupies a space of 2m X 4,20m - 8,4m². An Optimized Queue of 50 Link Barricades occupies a space of 2.22m x 3.20m - 7.1m²

Stacking on 3 levels, the same 8.4m² store 150 barricades in standard mode and 186 barricades in optimized mode.

What will determine the amount loaded will be the internal length of the truck body or trunk.

For transportation of quantities over 50 units, we recommend trucks with body width or trunk above 2.30m, because the optimized queues have up to 40% better use than the standard in transportation.

For trucks with a width of less than 2.25m, only the body models, which can be folded down, enable optimized queuing.

| Model | Lenght | Width | Standard | Optimized |

|---|---|---|---|---|

| Utility | 3,0 | 1,8 | 6,2 | 90 |

| Box Truck | 4,2 | 2,1 | 96 | 140 |

| Medium truck | 6,5 | 2,4 | 165 | 236 |

| Heavy Truck | 8,0 | 2,4 | 210 | 290 |

| Tank Truck | 14,5 | 2,48 | 400 | 550 |

| Cont. 20" | 5,9 | 2,35 | 146 | 210 |

| Cont. 40" | 12,04 | 2,35 | 328 | 450 |

The removable feet have movable parts, where their fittings have fragile spots, besides the vulnerability when mounted, the possibility of changing the position of the feet and the barricade to fall.

One-piece barricades are more stable and have no fragile spots.

None! For public restraint, heavy structures such as barricades that can be bolted in line must be used.

All the riots and protests in the world have shown the inefficiency of using iron bars in these situations and have shown their violent potential in these uncontrolled situations.

The barricades are only signaling and disciplining elements.

Link Barricades support winds, but they are not immune to their action, mainly in great proportions.

For applications in areas with high wind speeds or for small mounts exposed to weather, we recommend the attachment of our counterweight accessory to the feet of the barricades.

Yes! For fixed applications, the barricades can be bolted to the floor; for greater flexibility, we recommend the use of U type clamps by locking the feet of the barricade.